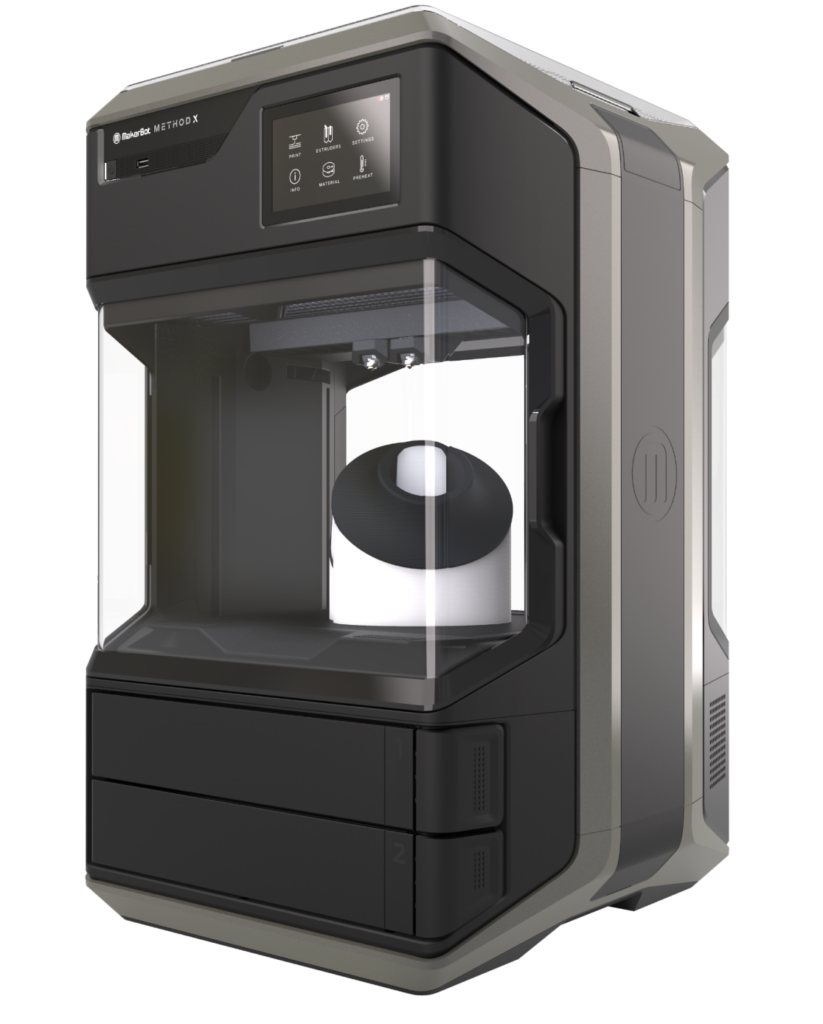

Print manufacturing tools and production parts to spec with ABS and a new game-changing tap water-soluble support material that dissolves easier, cleaner, and faster than anything else. All on the only 3D printer capable of repeatable ABS parts -the Method X.

Print technology : Fused Deposition Modeling (FDM)

Compatible filament diameter : 1.75 mm

Weight : 29.5 kg (65 lbs)

Maximum power output : 800 W

Layer resolution : 0.4 mm nozzle: 400 – 20 micron

Display : 5″ (12.7 cm) full-color capacitive touchscreen

Print head : Dual-extrusion print head with swappable extruders

Nozzle diameter : 0.4 mm

Maximum heated chamber temperature : temperature 110° C

Maximum extruder : 300° C temperature

Operating sound : 57.1 +/- 3 dB

Build plate : Flexible build plate

Supplied free software : CloudPrint

Supported OS : MacOS, Windows

File transfter : Wi-Fi, Ethernet, USB

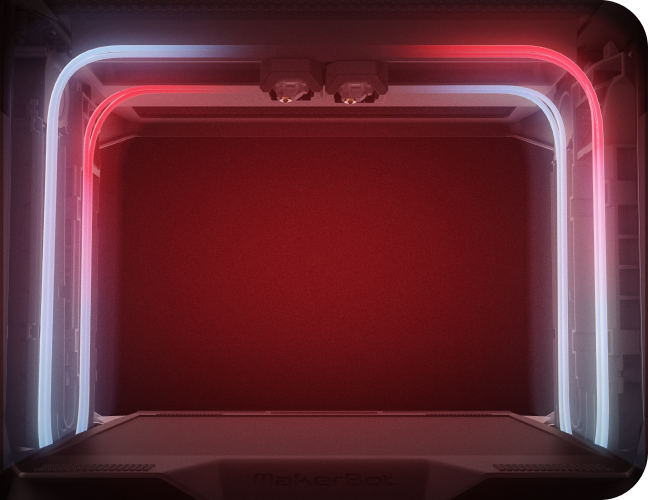

Patented VECT™ 110 Thermal Regulation evenly heats and controls the print environment leading to parts that are 2x stronger on the z-axis, and 2x more accurate across the board. (Variable Environmental Controlled Temperature)

Actively heated chamber

Maximum temperature:

Thermal Regulation evenly heats and controls the print environment leading to parts that are 2x stronger on the z-axis, and 2x more accurate across the board.

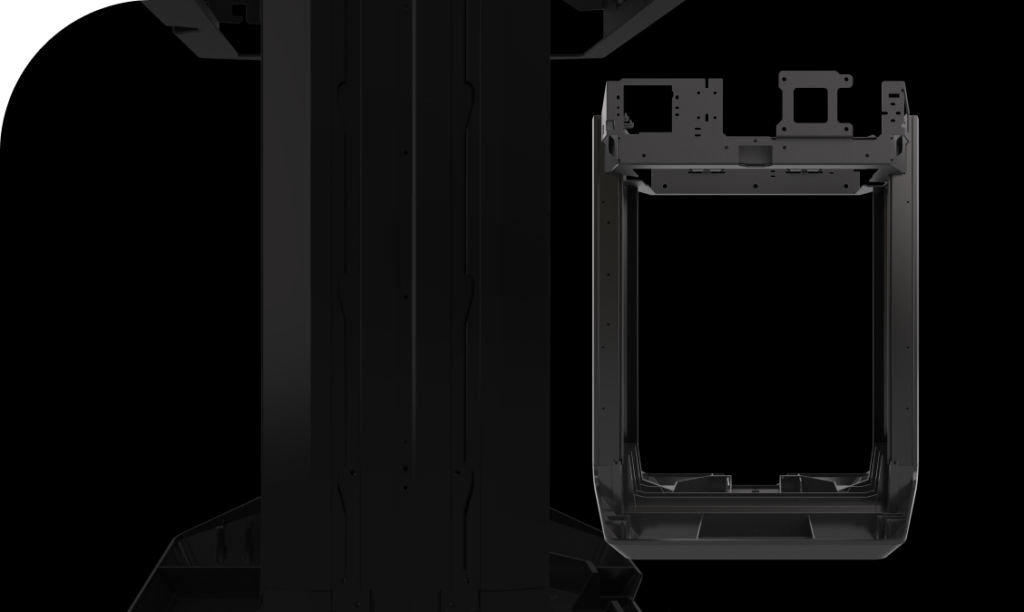

A structurally-optimized metal frame runs the full length of the body to offset flexing. Less flexing means more consistent prints with better part accuracy and fewer failures.

Dimensional accuracy

or +/-.002mm per mm of travel*

Quickly change between material groups, preventing cross-contamination.

Access an intuitive step-by-step setup and real-time controls and intel on your jobs.