Scale up your 3D printing output with the Method XL. Larger parts, increased output, and competitive pricing. Experience the precision of industrial production alongside the flexibility of a 3D printer.

Heated chamber max temperature : 100 °C

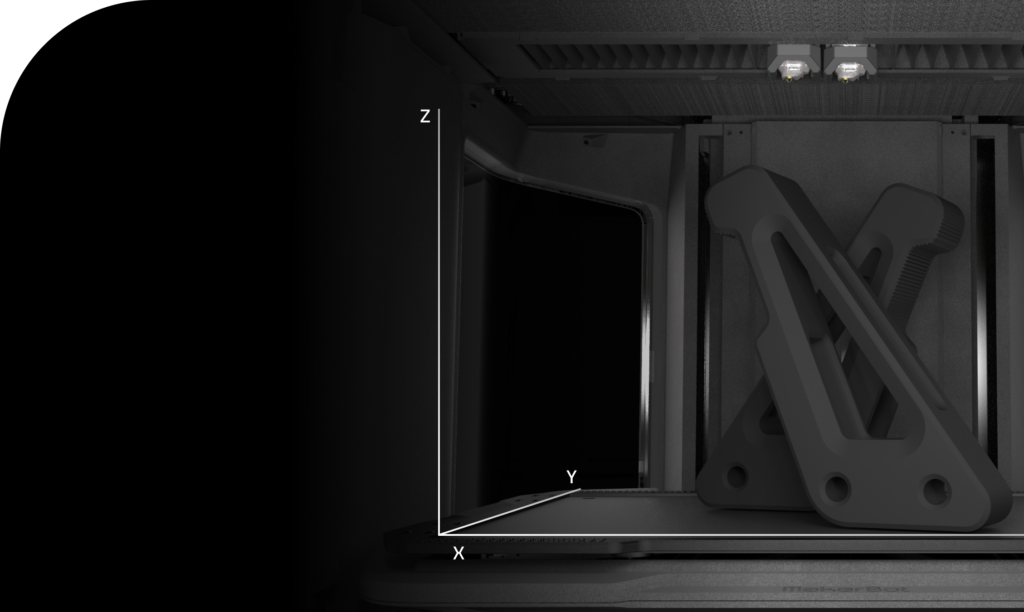

Dual extruder build volume (XYZ) : 305 x 305 x 320 mm (12 x 12 x 12.6 in)

Heated build plate : Heated build plate with removable, flexible build surface

Print technology : Fused Deposition Modeling (FDM)

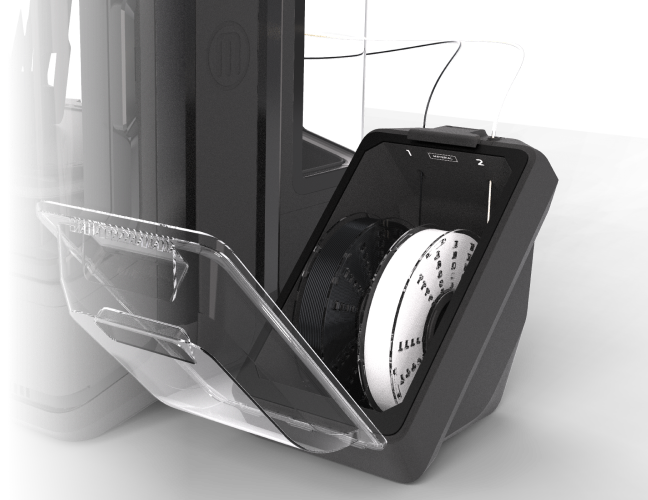

Compatible filament diameter : 1.75 mm

Weight : Printer: 56.5 kg (125 lbs)

Material case: 1.9 kg (4.2 lbs)

Maximum power output : 1400 W

Layer resolution : 0.4 mm nozzle: 100 – 400 micron

Display : 5″ (12.7 cm) full-color capacitive touchscreen

Extruder replacement : Swappable performance extruders

Print head : Dual-extrusion print head with swappable extruders

Nozzle diameter : 0.4 mm

Maximum heated chamber temperature : 100 °C

Maximum heated build plate temp : 105 °C

Maximum extruder temperature : 300 °C

Operating sound : 57.1 +/- 3 dB

Build plate : Flexible build plate

Supplied free software : CloudPrint

Supported OS : MacOS, Windows

File transfter : Wi-Fi, Ethernet, USB

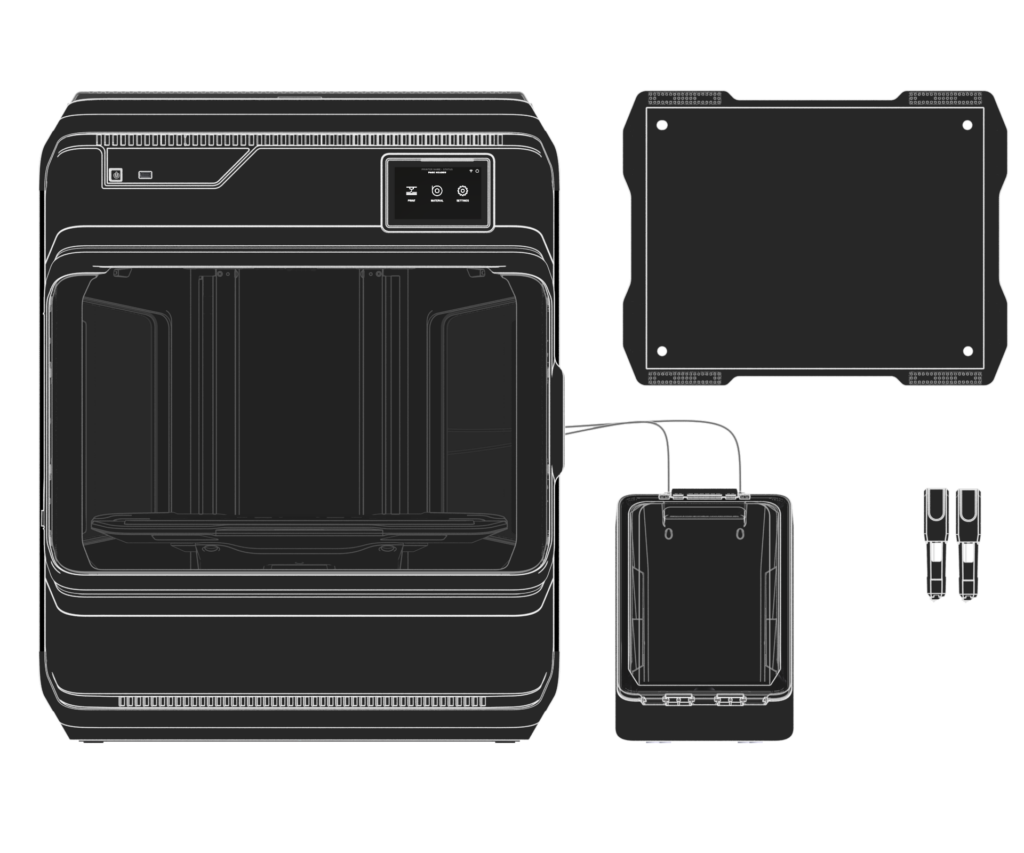

With the largest build volume of any UltiMaker 3D printer, the Method XL is the ultimate 3D printing solution for large-scale projects. Print with industrial-grade materials and exceptional dimensional accuracy without the need to compromise on the size of your parts.

Dual extrusion build volume (XYZ)

12 inches

12 inches

12.6 inches

Patented Variable Environmental Controlled Temperature (VECT) 100 thermal regulation evenly heats and controls the print environment. The result? Parts are 2x stronger on the z-axis, and 2x more accurate across the board. The Method XL also has a heated build plate for even better adhesion and temperature control.

Chamber actively heated up to

Build plate heated up to

The Method XL has been especially engineered to maintain dimensional accuracy and tight tolerances while printing even the largest ABS parts. Not only does the Method XL avoid warping and layer adhesion issues, but it creates massive parts with industrial-grade precision.

or +/-.002mm per mm of travel*

*(Whichever is greater.) Based on internal testing of selected geometries.

RapidRinse on the Method XL enables the fastest support removal for complex FDM prints. Create the geometries you want – in any orientation. Then watch as those water-soluble supports dissolve before your eyes.

Water-soluble supports for ABS

The Method XL’s external moisture-controlled material case ensures peak performance from your professional-grade materials.

Reliably 3D print with ABS-R or ABS Carbon Fiber to simulate the material qualities of injection molded plastics.

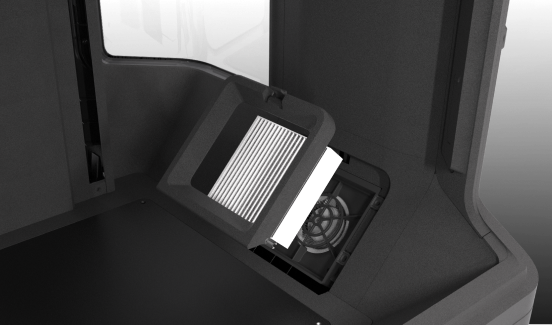

Both a HEPA filter and an activated carbon filter are integrated into the machine assuring that you can use the Method XL indoors without worrying about harmful fumes or strong smells.

Method XL includes: